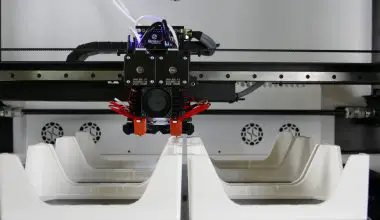

As technology in 3d printing has improved, the ability to make larger items as well as more detailed objects has become commonplace. Some manufacturers are using 3D printing technology to make lighter airplane parts, as well as small-scale models used to prototype new products.

3D printers can be used for a variety of purposes, but they are most commonly used in the manufacturing of consumer products, such as toys, jewelry, clothing, and furniture. They are also used by manufacturers to create prototypes for products that are not yet ready for mass production.

Table of Contents

How has 3D printing made an impact in productivity?

It allows you to produce prototypes quicker, reduces the cost of production, requires less input, and reduces overhead. Productivity and efficiency are greatly improved.

Why is 3D printing not used for mass production?

Mass-produced products using 3D printing can be difficult to make because the tolerances are not as tight as can be achieved with traditional methods. “We’re trying to make it as easy as possible for the end user to get the parts that they need,” .

How does 3D printing increase productivity?

Because 99 percent of prints are utilized directly in our production, this greatly increases production efficiency and quality control of outputs, which in turn increases the value of the final product.”. „We believe that 3D printers are the future of manufacturing, and we are excited to be a part of it.

How 3D printing is changing the world?

3D printing could make prosthetics cheaper for everyone, changing the lives of amputees worldwide. 3D printing is being used for surgery, with replicas of hearts and organs being used to help surgeons prepare. 3D printing that uses human cells and tissue is making its way into the medical field as well.

Companies such as Stratasys, which is based in Palo Alto, California, and 3d Systems, a company based out of Boston, Massachusetts, are two of the most well-known companies working in this field. In fact, the U.S. Food and Drug Administration (FDA) recently approved the use of 3-D printers for the production of medical devices, including prosthetic limbs and heart valves.

FDA has also approved a biocompatible material that can be used as a scaffold for tissue engineering. This material, known as biodegradable polyethylene terephthalate (PET), is used in a wide variety of applications, from biomedical research to the construction of scaffolds for transplantation.

How do 3D printers benefit society?

3D printing, most goods will be designed on computers and “manufactured” in the homes of consumers, thus reducing both the costs and the environmental impact of manufacturing. 3D printers are already being used to design and manufacture products such as medical devices, furniture, toys, and other consumer goods.

For example, it is not yet possible to print objects that are strong enough to withstand the rigors of everyday use, nor is it possible yet to produce objects with a high degree of precision.

In order to overcome these challenges, researchers at the University of California, San Diego (UCSD) have developed a new type of 3-D printer that is capable of producing high-quality objects at a fraction of the cost of traditional manufacturing methods.

Is 3D printing good for mass production?

3D printing is a suitable method for making products in mass. It can be used to help designers use another rapid prototyping process easily and less expensive, or it can be used to help designers make injection molds. 3D printers can also be used to make objects in a variety of materials, such as plastics, metals, ceramics, glass, wood, and so on.

In this case, the object is made by printing a layer of material on top of the previous layer.

This process is known as additive manufacturing (AM), and it has been used for a long time in the manufacturing of many different types of products, including toys, clothing, furniture, electronics, medical devices, etc. It is also used in many other industries, for example, in aerospace, automotive, food and beverage, cosmetics, pharmaceuticals, textiles, rubber, plastics and many others.

The main advantage of AM is that it does not require a large amount of space, which makes it more cost-effective than traditional manufacturing methods. For instance, it requires a lot of time and energy to print a single object.

How is 3D printing impacting businesses?

3d printing allows for small batches of parts to be created in only a few hours, one of the key impacts that 3d printing will have on businesses. The art of rapid prototyping allows businesses to test a new idea in days, rather than weeks or months.

The ability to print parts in a variety of materials, such as plastics, metals, and ceramics, has allowed for the creation of a wide range of new products and services. For example, in the past few years, companies have been able to create products that are lighter, stronger, more durable, or more energy efficient than ever before.

In addition, these products can be customized to fit a customer’s specific needs, making it easier for them to get the most out of their investment.

Why is 3D printing important for the future?

3D printing can produce parts, allow for changes without requiring extra tools or equipment in comparison to other methods. The world is fixated on the technology because of the future possibilities. New products and services that are not possible with traditional manufacturing techniques can be created with the help of 3D printing.

How is 3D printing used in production?

model. Complex objects can be produced quickly and at a low cost by using a 3D printer and adding material layer by layer. 3D printers are used to create objects that are made of a variety of materials, including plastic, metal, ceramics, glass, wood, paper, and more. They can also be used for the production of parts and components for a wide range of products, from toys to medical devices.

How is 3D printing can be a sustainable manufacturing method?

3D printing is the process of building an object layer by layer. It does not use up more material than it needs. It doesn’t produce as much waste as traditional manufacturing methods, but it does produce less waste. 3D printers can also be used to create complex objects, such as medical devices, which require a lot of material to be created.

In this case, the material used is typically plastic, but it can be made from a variety of materials, including metals, ceramics, and polymers. This process can take up to a week, depending on the size and complexity of the object being made.