A ball pein or a cross pein hammer is enough to start. These are usually found at local hardware stores. You can get various types of hammers from the blacksmith supply house. You will be able to make your own when you develop some blacksmithing skills. Once you have a hammer, it’s time to learn how to use it. There are a number of ways to do this.

The most common way is to hold the hammer in your left hand and use your right hand to strike the wood. This is called the left-handed hammer method. If you’re left handed, this is the easiest way to get started.

Table of Contents

Can you make Damascus steel?

Damascus steel can be created in a few steps. To make damascus steel, you’ll need to gather the necessary tools and materials, assemble your steel, heat the steel, temper the steel, and then finish it. Gathering the Tools and Materials to Make Damascus Steel The first step in making steel is gathering all of the materials needed to make a billet of steel.

You can gather these materials in a variety of ways, but the most common way is to buy them from a local steel mill. If you don’t have access to one of these mills, then you can make your own steel by following the steps below. This is a great way to get started on your journey to becoming a master of Damascus steel making.

What is the easiest metal to forge?

It will stay mallable for a long time and heat easily, and copper is a great material to forge. There are any type of steel forges available. It is possible to find high carbon steel for knives and tools in the form of stainless steel. Heat treating is the process of adding heat to the steel to make it harder and more resistant to corrosion.

Heat treating can be done in a variety of ways, but the most common method is to heat it to a high enough temperature to melt it. This is done by placing a small amount of molten metal into a crucible. The metal is then heated until it reaches a temperature where it begins to solidify.

Once the metal has solidified, the heat is turned off and the material is allowed to cool to room temperature. It is important to note that heat treating does not affect the strength of the blade, only the hardness. If you have a knife that has been heat treated, you should be able to use it without any problems.

Can you forge with wood?

Don’t use wood that may have been exposed to the elements. It depends on the type of sword you are forging, but it can take anywhere from a few hours to a couple of days depending on your skill level and the quality of the wood you use.

The longer the sword is forged, the more difficult it will be to finish. If you want to get the most out of your sword, you should forge it as soon as possible after you receive it from the manufacturer.

What type of coal is used for forge?

The coal of choice for the blacksmith is Bituminous Coal. The coal is soft and black. It burns cleaner than lignite because it is mined from deeper mines. We keep a stock pile of wet coal on hand so that we don’t run out of coal when we need it.

Copper Ore Copper ore is one of the most common ores used in smelting, and is used to make a wide variety of metals, including iron, copper, tin, lead, silver, gold, platinum, palladium, rhodium, bismuth, tungsten, molybdenum, zirconium and many others.

Copper is also used as an alloy with other metals to create alloys that are stronger, lighter and more resistant to corrosion than their base metals. The most commonly used alloy is copper-nickel-zinc (CuNiZn), which is often referred to as “copper-alloy” or simply “alloys”.

Can you teach yourself blacksmithing?

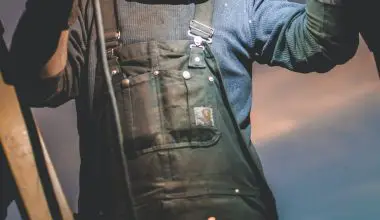

It is possible to set up your own shop once you have learned the basics from a professional blacksmith. You will need the following equipment: A hammer and a chisel (or a pair of chisels if you don’t have a hammer). A hammer can be purchased at any hardware store, or you can make one yourself with a few pieces of wood and some nails.

If you have access to a drill press, you may also be able to use it to make a small hole in a piece of plywood and drill a hole for the hammer. A small drill bit is also a good idea, as it will make it easier to drill the holes in the wood, and will allow you to get a better grip on the material you are working with.

An electric drill will also work, but you will have to be careful not to over-drill the hole, since this will cause the metal to melt and cause a lot of damage to the workpiece. The best way to do this is to hold the drill with one hand and use the other hand to tap the bit into the surface of the piece you want to work on.

What do modern blacksmiths make?

Modern-day blacksmiths use wrought iron and steel. They use the same tools as their ancestors, including hammers, anvils and pliers, to make metal. Depending on the job, they can make a variety of tools and implements. Blacksmithing is a highly specialized trade, requiring a high level of skill and knowledge.

It is also a very dangerous profession, with the risk of injury and death being a common occurrence. In fact, the Blacksmith is the only profession that requires a license to work in the United States.

What does a whitesmith do?

A whitesmith does finishing work on iron and steel such as filing, lathing, burnishing or polishing. The term refers to a person who works with white or light-coloured metals, and is sometimes used as a synonym for a blacksmith.

What is the best refractory for a forge?

ITC-100 is known for its ability to reduce fuel costs and help your forge reach higher temperatures in a quicker time frame. ITC-100 can help reduce the amount of flux that you have to deal with in the first place.

I’m not going to go into too much detail here, but suffice it to say that I’ve been using it for a while now, and it’s been a huge help to my forge. If you’re interested in learning more about it, you can check out the wiki page for more information.