Loctite epoxy weld bonding compound can be used to glue metal. It’s the strongest solution for bonding most metals, including iron, steel, aluminum, brass, copper, nickel, and stainless steel. It can be used to bond metal to wood, plastic, fiberglass, glass, or any other non-metallic material.

If you’re looking for a more permanent solution, you can use epoxy resin. This is the same stuff that’s used in the construction industry to make concrete. You can buy it at most hardware stores, but you’ll need to find a supplier who can ship it to your home.

Table of Contents

How do I permanently join metal?

The process of riveting involves the use of mechanical fasteners to create a permanent bond between two metal surfaces. A punched hole is used to insert the rivet, a metal fastening featuring a cylindrical post with a head.

How do you get metal to stick to metal?

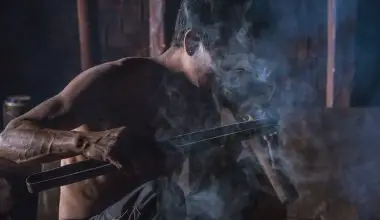

The method of connecting two metal parts is referred to as the brazing method. The metal is heated to a temperature of over 800 degrees. This method is less expensive than welding. It’s similar to using an glue rather than melting the metal. “It’s a very simple process, but it requires a lot of skill and experience to get it right,” .

How do you stick metal to metal?

Cyanoacrylate, also known as instant adhesive, is the super glue for metal to metal bonding. As long as they are reactive, conjugateacrylate is a good choice for most metals. The glue for metal works better on brass and copper than on other metals. Apply a small amount of the adhesive to the metal surface and let it dry for a few minutes.

Then, apply a thin layer of another adhesive on the same surface. Let the second layer dry. Repeat the process until the entire surface has been covered with the two adhesive layers. This process can be repeated several times to cover all the surfaces of a piece of metal.

Is metal glue as strong as welding?

Structural adhesives, when used with the right design, are as strong or stronger than welding. They can improve your manufacturing processes by eliminating the labor and time costs associated with metal preparation and finishing operations. When it comes to the many benefits of using structural glue, that’s only the beginning.

What are the methods of joining metals?

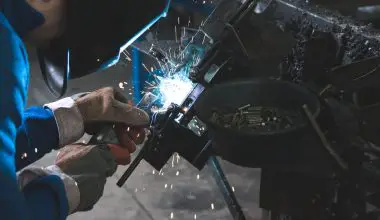

Bolting, riveting, caulking, shrink fitting, and folding all use mechanical energy to join. fusion welding, pressure welding and brazing/soldering use heat and pressure to join metal parts together. Electrical joining is the process of joining two or more electrical devices together using electrical energy, such as a battery or a circuit breaker. Electrical joining can also be used to connect electrical equipment to a power source.

Is soldering like welding?

The main difference between welding and soldering is melting. In soldering, metal producers heat up the metal to be bond but never make it softer. In welding, metal producers melt the material and then heat it up to bond it. MATERIAL. WELDing is the process of heating a material to a high temperature, then heating it back down to its original temperature.

This process is used to make a wide variety of materials, including plastics, metals, ceramics, glass, rubber, paper, and many others. It is also used in the production of many other products, such as paints, coatings, adhesives, lubricants, paints and varnishes, as well as many types of electrical and electronic equipment.

Does Gorilla Glue work on metal to metal?

GorillaWeld is a heavy duty steel bond. The formula has a strong bond and can be set in 10 minutes. A long lasting, permanent bond to metal, plastic, concrete, ceramics, fiberglass, wood, and more can be created with GorillaWeld. *PVC is not recommended for use with this product.

What tool is used to join two pieces of metals?

When connecting two or more pieces of heavy section metal, rivets are used. Light gauge sheet can also be joined. It is necessary in heavy sections such as, Bridge, Wagon, Tanker, Boiler and so on. The rivet is used to fasten a piece of metal to a joint or to join two parts of the same metal together.

The most common type of riveted joint is the one made by riveting the two ends of a metal bar to each other. This is called a “double joint” or “triple joint”. In this joint, the metal bars are fastened together by means of an iron bar, which is attached to the end of one bar and to which the other end is connected by a screw or other fastening device.

When the screw is tightened, it pulls the bar in the direction of its motion, thus making the joint more rigid and more resistant to wear and tear. However, this is not the only way to make a double joint. Another way is to use a rivetted joint which consists of two bars joined together at one end, and a third bar attached at the opposite end.