Table of Contents

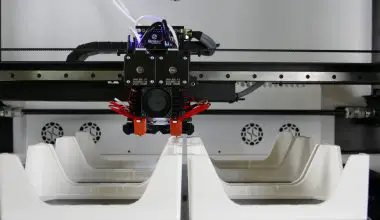

Can I build a 3D printer from Arduino?

4 DIY Arduino 3D Printers You Can Build. Even it there are a lot of 3D printer kits around, pure DIY Arduino 3D Printer kits have become a rarity. We found three of the most popular 3D printers that you can build your own from. Read on to find out how to build your own. The Replicators are great for beginners because they are cheap and easy to use.

They also have a built-in LCD screen that allows you to control the printer from your smartphone or tablet. You can also print with PLA, ABS, HIPS, PETG, and other materials. This is a great option if you don’t want to spend a ton of money on a printer. It’s a metal printhead that can be used with a variety of materials, including PLA and ABS.

Is building a 3D printer hard?

It’s very difficult if you’re designing it on your own. It would require a lot of time and expertise. It is easy to build from a kit if you are standing on the shoulders of giants. It can be done in a single day.

Is building a 3D printer worth it?

It is technically speaking, yes. It’s cheaper to build your own 3D printer from scratch than it is to purchase an assembled 3D printer. Purchasing 3D printer parts isn’t cheap either. 3D printing is a great way to learn how to make things, but it’s not the only way. There are a number of other ways to get started making things.

How much does it cost to run a 3D printer per hour?

1.58 cents is the cost per hour for electricity and the average power draw of a 3d printer is 125 watths. 3D printing is still in its infancy, but it is already being used to make some of the world’s most complex objects, such as prosthetic limbs.

Can you 3D print concrete?

Cementitious 3D construction printing (3DCP) or 3D concrete printing is a form of Additive Manufacturing used to fabricate buildings or construction components in completely new shapes, not previously possible using conventional methods. The process is based on the use of a liquid resin, such as polyethylene terephthalate (PET), which is then mixed with a polymer resin.

The mixture is heated to a high temperature, causing the resin to harden and solidify. This solidifies the polymer into a solid, which can then be extruded into the shape of the desired object. In this way, the material can be used in a wide range of applications, including building construction, automotive parts, medical devices, and other products.

Does 3D printing save money?

3d printing can save money at home and in the office. 3D printers can be used to create basic office supplies at a lower cost than buying them off the shelf. 3D Printers for the Home and Office 3d printers are great for home use, but they can also be used for office use as well. You can use them to make a variety of items, from desk accessories to office furniture.