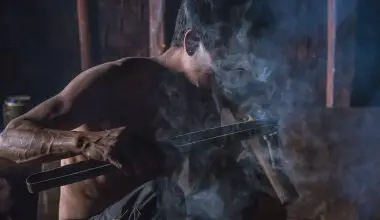

CMT welding performed by Elrefaey was found to produce joints with mechanical characteristics better than the conventional MIG and TIG processes and comparable to FSW and LBW processes [19]. The weld zone is defined as the area between the welds. A cross-section of the welding zone. Cross-sectional view of a welded joint.

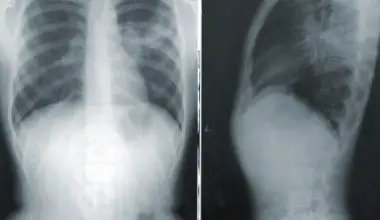

The cross section is shown in the lower left corner of each image. In the left image, the center line is at the point of weld penetration, and the right image shows the same area as in (C) but with the line of penetration shifted to the upper right.

This material is not visible in either image because it is too small to be seen with a microscope, but it can be clearly seen in a scanning electron microscope (SEM). SEM image of (D) shows an area of approximately 0.1 mm2, which corresponds to a thickness of about 1.5 μm.

Table of Contents

What is CMT arc welding?

When detecting a short circuit, it works by reducing the weld current and pulling the wire back, resulting in a drop-by-drop deposit of weld material. It requires strict control of the welding process to be developed for thin materials.

What is CMT from Fronius?

Transfer) welding process allows users to achieve optimum results when joining different materials, for example, stainless steel, aluminum, copper, brass, and aluminum alloys. CMT is a process that uses cold metal to transfer heat from one material to another. This process is used in a wide variety of industries, including aerospace, automotive, medical, aerospace and defense, as well as many other industries.

What is cold MIG welding?

Cold welding, also known as contact welding, is a solid-state welding process that requires little or no heat or fusion to join two or more metals together. The energy used for creating a weld comes in the form of heat, which is melted and fused with the other metal.

Contact welding is the most common type of welding used today, but it is not the only type. For example, you can use a heat gun to heat up a piece of metal and then heat it up again to form a bond. You can also use an electric arc to create a welding bond between two metal parts.

What is RMD welding?

Miller’s regulated metal deposition (rmd®) mig welding process (modified short-circuit mig) improves welding quality and productivity. RMD process is easy to learn and addresses the welder shortage by providing an easier process that gets more work done faster and at a lower cost.

What is double pulse GMAW welding?

Compared with conventional GMAW, theDP-GMAW has many advantages, such as reduced porosity incidence and improved solidification properties. In this study, we investigated the effect of a high-temperature, low-pressure (HT-HP) welding process on the performance of an ultra-high-strength (UHS) stainless steel (SWS) electrode.

SWS electrodes were fabricated from a stainless-steel alloy (0.5–1.0 wt. %) with a diameter of 0.8 mm and a thickness of 1.2 mm. The electrode material was selected because of its high tensile strength and high thermal conductivity [11,12].

What is globular transfer welding?

During welding, large droplets or globs of the welding wire — typically irregular in shape and larger than the wire diameter — transfer across the arc into the weld pool. This transfer occurs at higher wire feed speeds and voltages than short-circuiting, which occurs when a small droplet or blob of wire is transferred across an arcs at a lower speed and voltage.

In the case of globular transfers, the transfer takes place over a relatively short period of time, typically less than a second or two. The transfer can occur in a variety of ways, such as when the metal is heated to a high enough temperature to vaporize it, or when it is exposed to high-voltage current. In either of these cases, it can be difficult to distinguish between the two types of transfers.

What is CMT and FOB?

This distinction is important because it allows for a more flexible approach to production, as well as a greater degree of control over the supply chain. However, in order for this to happen, both parties must agree on a price, and this price must be agreed upon by both the producers and the buyers.

If the price is not reached, neither party will be willing to pay the agreed price. As a result, production will not take place and neither will the goods be sold to the other party. The producer will have no choice but to shut down production and sell his or her products to someone else.

What does arc length correction do?

Thearc length correction feature ensures that deep penetration is occurring, while avoiding undercutting, when set to the shortest possible length. Maintaining higher welding temperatures is helped by this.

These include the use of a high-temperature arc-welding torch, as well as the ability to control the flow of molten metal through the welding arc.

For example, if you are welding a large area of metal, you may want to use a longer arc than you would for a smaller area, or vice versa.