Dross is a mass of solid impurities floating on a molten metal or dispersed in the metal, such as in wrought iron. It forms on the surface of low-melting-point metals such as tin, lead, zinc or aluminium. Dross can also form on metals that have been heated to a high enough temperature to melt them. The most common cause of dross on metal surfaces is oxidation.

Oxidation occurs when a metal is exposed to an oxidising agent. For example, iron is oxidised by sunlight to form iron oxides (Fe2O3) and zinc oxide (ZnO2). The oxidation process is reversible, however, and the iron oxide can react with other metals to produce a new form of iron or zinc.

This is known as the ‘oxidation reaction’ and is responsible for the formation of many metals, including aluminium, copper, nickel, cobalt, manganese, molybdenum, selenium, tungsten, vanadium and zirconium. In the case of zinc, the oxidation reaction can be reversed by heating the zinc to high temperatures and then cooling it back down to its original state.

Table of Contents

What is dross on steel?

Dross is defined as a byproduct of the galvanizing process that forms by reactions between molten zinc and loose particles of iron in the galvanizing kettle. The basis of hot-dip galvanizing is a reaction between iron in steel and molten zinc.

The best way to determine if your kettle has reached the proper temperature is to use a thermometer to measure the temperature of your hot water. If the water is at or above the boiling point of water, the kettle should be at the correct temperature for the type of galvanizer you are using.

What is the difference between slag and dross?

Dross product can be recycled and used in secondary steel making. Aluminum is the second most abundant element in the earth’s crust. It is found in a variety of forms, such as aluminum oxide, aluminum hydroxide, and aluminum sulfate. Aluminum is also found as a byproduct of the smelting and refining of other metals, including copper, lead, zinc, iron, magnesium, nickel, cobalt, manganese, silver, tin, tungsten, chromium, bismuth, molybdenum, vanadium, platinum, rhodium and palladium.

What is lead dross?

Dross is a mass of solid impurities floating on a molten metal bath. It appears on the melting or oxidation of low melting point metals such as tin, Lead, zinc or aluminum. Dross can also be formed in the presence of high temperatures and/or high pressures.

The term “dross” is sometimes used to refer to any solid or liquid that has been heated to a high enough temperature or pressure to form a solid. The term is often used as a synonym for “waste” or “garbage” in reference to waste products.

What causes dross?

As you probably know, mild steel melts at a much lower temperature than the laser beam can produce. If we overheat the material, we get dross. If the power is too high, the heat will cause the steel to oxidize. The solution is to use a high-power laser to heat the metal to a very high temperature.

This is called a superheated laser, and it is used in a variety of industries, including the aerospace industry. It is also used for the production of superconducting magnets, which are used to conduct electricity. Superconductors are very difficult to work with, but they can be very useful in some applications. For example, they have the advantage of being very strong and very conductive.

They are also very expensive to produce, so they are not used as much as they could be. In the medical field, it would also be a useful material for magnetic resonance imaging (MRI), which uses magnetic fields to image the inside of the body.

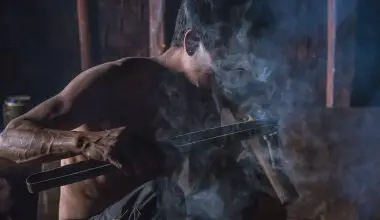

How is dross removed?

Use an anti-spatter spray, such as Clean Strike. Anti-spatter spray is inexpensive, fast, and easy to apply and some formulas are non-toxic and eco-friendly. It will be easier to clean if dross is prevented from adhering to the plate. Clean the surface with a mild soap and water.

If you don’t have a dishwasher, you can use a regular dishwashing detergent, but be careful not to use too much, as this can cause the dish to become clogged. You can also use an alcohol-based cleaner to help remove the dirt and grime that may have accumulated over the years. Rinse your plate with water and let it dry completely before re-applying the coating.

The coating should be completely dry by the next time you use it.

How do you remove impurities from molten metal?

Adding deoxidants, usually Silicon or aluminum, and the addition of magnesium to certain alloys are some of the things that can be added to Molten Metal Technologies.