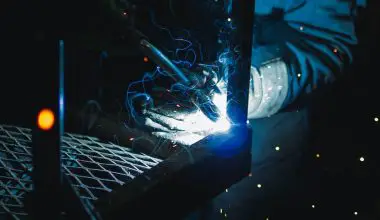

The wire is coated with metal. It is similar to the metal that is being welded. Shield metalarc welding (SMAW) also known as stick, which means that the electrode can be removed from the shield and replaced with a new one at any time, is a type of stick welding. Shield Metal Arc Welding (SMAW) is one of the most common welding techniques used in the automotive industry.

SMAW involves welding a metal shield with an electrode. The shield is heated to a high enough temperature to melt the electrodes, and the molten metal is passed through the welding process to create a weld. This technique is used to weld a wide variety of metals, including aluminum, steel, copper, aluminum alloys, titanium, magnesium, stainless steel and many others.

Table of Contents

What are 4 types of welding electrodes?

All-position welding capability is offered by each of these electrodes. Stick welding can be performed in a variety of ways, depending on the type of material being welded.

For example, it is possible to stick weld a piece of sheet metal to a sheet of plastic, or to weld two pieces of steel to each other.

In either case, the end result is the same: a weld that is strong enough to support the weight of the entire assembly.

What are basic electrodes?

It is basic. Excellent mechanical properties can be found in basic electrodes. The coating has low-hydrogen iron powder, TiO2, CaCO3 and CaF2 in it. The thickness of the coating is medium and the addition of an electrolyte increases it. Electrolytes are added to the electrodes to increase the electrical resistance of the device. Electrolyte additives include sodium hydroxide (NaOH), calcium chloride (CaCl2), and potassium hydrate (KH2O).

These additives can be added in the form of a solution or as a powder. In the latter case, the solution must be heated to a temperature of at least 100°C (212°F) to dissolve the additives, which are then dissolved in a suitable solvent such as methanol or isopropyl alcohol. This solvent is then evaporated, leaving behind a residue that is mixed with the electrolytes to form the final electrode material.

How many electrodes are used in welding?

Depending upon the process, there are two types of welding electrodes. There is a non-consumable. The consumable electrodes are the ones that are used in the manufacturing process. The non-consumables are those that can’t be used for the production of the product. For example, if you want to make a car, you have to buy a battery, a motor, and a transmission. If you don’t have any of these things, then you need to use a disposable electrode.

This is the type of electrode that you can buy at a welding supply store. You can also buy disposable electrodes at your local auto parts store, but they are not as good as the consumables. They are more expensive, so you should only use them when you really need them. There are a few things to consider when choosing the right electrode for your welding project.

First of all, make sure that the electrode you choose is compatible with the project you are working on. It is very important to choose the correct electrode because it will affect the quality of your weld. Also, it is a good idea to read the instructions that come with your electrode before you start welding.

What is the use of electrode?

It is possible to provide current through nonmetal objects to alter them in a variety of ways. Measures of electrical resistance, voltage, current, and current density are included in the examples. Electromechanical devices (EMDs) are devices that use electromagnetism to produce mechanical force. EMDs include electromagnets, motors, generators, transformers, capacitors, inductors, diodes, transistors, resistors and other devices.

What is electrode size?

The thickness of the part that will be welded determines the size of the electrode that should be used. The metal to be welded is larger than the electrode for thin metals. If the plate is 2.0mm thick, the required size would be 0.5mm. For thicker parts the electrodes are larger and more complex. In this case it is best to use a larger diameter electrode. The larger the diameter the greater the potential difference between the two electrodes.

This is because the larger electrode has a greater surface area to dissipate the heat generated by the welding process. It is also the case that the higher the temperature the more energy is required to heat the material to a high enough temperature to melt it. As a result, larger electrodes will have a higher melting point than smaller ones.

What are the two types of electrode?

There are two types of electrodes, reactive and inert. An inactive type does not participate in any reaction. In the case of an inert electrode, there is no current flowing through it.

This type of electrode can be used in a wide range of applications such as medical devices, medical imaging equipment, etc. Reactive Electrode A reactive electrode is an electrode that reacts with an external magnetic field to produce an electric current. Reactive electrodes have been used for a long time in the medical field. They are used to diagnose and monitor the health of the patient.

The use of reactive electrodes has been increasing in recent years due to their ability to detect and diagnose diseases and injuries.

What is electrode angle?

The plane where the travel angle is measured is defined by the weld axis and the electrode axis. The angle between the reference plane and the electrode is called the travel angle. Travel Angle of an Electrode. The distance between two reference planes is known as the travel distance.

For example, if you are measuring the distance from one electrode to the other, you can use the following formula to determine how far away the two electrodes are from each other: (distance between electrodes) x (travel distance) = distance to other electrode. This formula can also be used to measure the length of a wire, as shown in Figure 2: Distance between Electrodes x Length of Wire = Distance to Wire.

In this case, the wire length is 1.5 meters, which is equal to 0.75 meters. If you want to know how long it will take for the wires to reach their destination, use this formula: distance x length = time to destination = (time to wire) / (length of wire). This equation can be written in the form: time = length x distance = travel time.

What is electrode coating?

A mixture of minerals, organic material, ferro-alloys and iron powder is bonded with sodium or potassium silicate. The metallurgy of welding and casting was published. The following materials were used in the preparation of the electrode coating: (1) alumina, (2) aluminum oxide (Al 2 O 3 ), (3) copper sulfate (CuSO 4 ) and (4) zinc sulfide (ZnS 2 ).

The coating was prepared by the following methods: 1. Alumina was dissolved in a solution of sodium hydroxide in methanol. The solution was heated at a temperature of 100° C. for 30 min. and then cooled to room temperature. After cooling, the mixture was filtered through a fine mesh screen and the filtrate was evaporated under reduced pressure to dryness.

It was then washed with water and dried in an oven at 50°C. (5) Aluminum oxide was obtained by dissolving aluminum powder in acetone and evaporating the resulting solution.

What are the parts of electrode?

The working, reference, and auxiliary electrodes make up the three-pronged system. In voltammetry, the three electrode system is important. A unique roll-off function is served by all three of these electrodes. Reference electrode is the electrode that is used to measure the current flowing through the circuit. It is also referred to as the “reference” electrode because it serves as a reference for the other two electrodes.

When the voltage across the two reference electrodes is equal to or greater than the reference voltage, the three-electrode circuit is considered to be in a stable state. In other words, all three electrodes are working at the same time. This is called a “stable state” or “steady-state” condition. If the voltages are not equal, then there is a potential difference between the electrodes, which can lead to a voltage drop across one or more of them.

For example, if a current is flowing from one electrode to the second electrode and then back again, this could cause a drop in the third electrode’s voltage. As a result of this potential drop, current will flow from the first electrode back to its original source, causing an increase in its voltage and a decrease in that of its second counterpart.