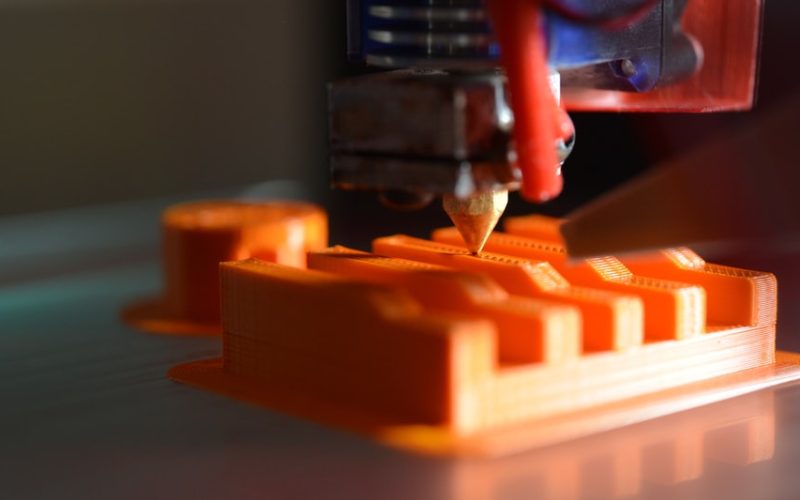

FDM is a type of 3D printing. 3D printers and production grade thermoplastics can be used to build objects out of a variety of materials. The benefits are many, but the most important is the ability to create objects that are accurate to within a few microns. This is important for a number of reasons. First, it allows for the creation of complex shapes that would otherwise be impossible.

For example, if you wanted to make a 3-D-printed gun, you would need to be able to accurately model each and every part of the gun. If you were to try to model the entire gun from the top to the bottom, there would be no way to do it accurately, and you’d end up with a gun that was too large and unwieldy to actually use.

With a model like this, the only way you could make it accurate is to use a high-quality thermoplastic material, such as ABS or PETG, which are both extremely strong and durable. Second, using the right material allows you to control the size and shape of your object, making it much easier to print.

Table of Contents

Is FDM and PLA the same?

FDM is probably the most popular 3D printing technology. It is also referred to as FFF. PLA is flexible and easy to work with, while ABS is heat resistant and strong. In this tutorial, we are going to learn how to print with FDM.

We will be using a Makerbot Replicator 2, but the process is the same for any other printer. This tutorial assumes that you have a basic understanding of how a printer works.

What is the difference between FDM and 3D printing?

FDM 3D printers create layers by depositing molten material. Each layer can be as thin as a single atom with the help of a highly-precise laser. “SLA printing has the potential to revolutionize the way we design, manufacture, assemble, and repair our products,” said Dr. Michael J. O’Donnell, a professor of mechanical engineering and materials science and engineering at the University of Illinois at Urbana-Champaign.

“We are excited to be able to bring this technology to market in the U.S., and we look forward to working with the industry and the community to make this a reality.” The research was supported by the Defense Advanced Research Projects Agency (DARPA), the Office of Naval Research, the National Science Foundation (NSF), and a National Institute of Standards and Technology (NIST).

Which is stronger FDM or SLA?

The strength and mechanical performance of FDM materials such as nylon, polycarbonate, and other tough materials are comparable to the strength and mechanical performance of a piece of SLA. 3D printing is more expensive and yields less parts per unit of material. SLA Resins are also more expensive to produce than other types of 3d printed parts.

This is due to the fact that they are made from a very thin layer of resin, which requires a lot of heat to melt and harden. In addition, the resin has to be removed from the print bed before it can be used to make a new part.

Because of these factors, it is not possible to print a large number of parts in a short amount of time. The only way to achieve this is to use a high-temperature extruder and a hot-end that is capable of printing at very high temperatures.

Which is better FDM or resin?

While the quality of pricey FDM printers such as PLA, PETG and nylon is still very good, resin printers are generally considered to be the best choice for 3D printing. Resin printers can be used for a wide range of applications, from prototyping to large-scale production.

They can also be useful for hobbyists who want to print their own parts, but don’t have a lot of time or money to invest in a high-end machine.

Is FDM printing strong?

A large number of plastic-like materials can be printed with a FDM printer. The wire is used to introduce this filament. The material is extruded by the 3D printer. 3D printing is a relatively new technology. Since then, the technology has become more and more sophisticated, and it is now used in a wide variety of industries, including aerospace, automotive, medical and consumer products.

Is SLS stronger than FDM?

SLS offers printing in nylon only, whereas FDM offers printing in a wide range of materials. The parts that are printed in SLS are more durable than those that are printed in FDM. The properties of the two materials are different. SLS is a material that can be used for 3D printing because of its high strength and durability.

However, it is not as strong as ABS, which is the most commonly used material for printing. This is because ABS has a higher melting point than PLA and is therefore more prone to warping. PLA is also more expensive than ABS. The reason for this is that ABS is made from a mixture of different materials, such as polylactic acid (PLA), polyurethane (PETG) and polypropylene (PP).

These materials have different melting points and are therefore not compatible with each other. For example, PLA melts at a lower temperature than PPG and PP. Therefore, if you want to print ABS parts, you will need to use a different material than the one you are using for PLA.

Is Markforged a FDM?

Markforged printers have been designed to produce high strength and high quality prints. The material Markforged designed, ONYX, has a high tensile strength. This material is used in the production of many of the world’s most popular products. Onyx is available in a wide range of colors, including black, white, red, blue, green, yellow, orange, purple, pink, brown, gray, and white. It is also available as a single color filament.

Are resin printers cheaper than FDM?

You will need to replace both the tanks and the printers frequently. The cost of a tank is around 40 dollars, and the cost of a liter of resin is around 80 dollars. An FDM printer is more expensive than a 3D printer, but the difference is not significant.

3D printing is a great way to get your hands on a lot of materials at a very low cost. However, there are a few things to keep in mind before you start printing. First of all, the quality of the finished product will depend on the printer you use.

If you are using a high-end printer like the Makerbot Replicator 2, then you should be able to print pretty much anything you can dream up. On the other hand, if you have a cheap printer that can’t print very well, it might not be the best choice for you. Also, don’t be afraid to experiment with different materials to see what works best for your project.

You might be surprised by what you find.

Are resin printers faster than FDM?

Laser-based resin printing tends to be slower than FDM. It takes more time to cover each layer because of the small surface area of the lasers. There are more post-processing steps in resin printing than there are in FDM. In a fraction of the time, projector- and LCD-based printing can be done.

Laserjet printers use a laser to heat a liquid resin to a specific temperature, which causes the liquid to solidify. This process is very fast, but it requires a lot of energy. Laser printers, on the other hand, are much more energy-efficient, and can print at a much lower temperature. Because of this, laser printers are often used for prototyping and small-scale production.

Is ABS toxic to print?

There are odors and emissions. The odor commonly known as burnt plastic is caused by a strong odor when printed. The smell of the printer can make it very uncomfortable to stay in the same room as it is being used, and it can also be a health hazard to those around you.

ABS is also known to emit emissions that can be harmful to the environment. These emissions include carbon monoxide, carbon dioxide, nitrogen oxides, and volatile organic compounds (VOCs). These VOC emissions can cause health problems for people who are sensitive to them, such as those with asthma, heart disease, or lung cancer.