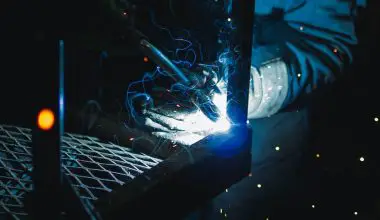

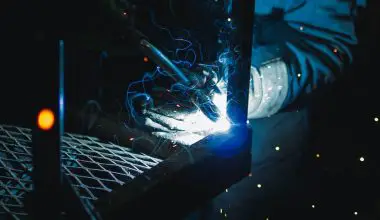

Constant current systems, as well as alternating current, can be used with gmaw, but a constant voltage, direct current power source is the most commonly used. This is the most common method of transfer. A globular circuit is made up of a series of resistors, capacitors, and inductors. Each of these components is connected in series with the other. The series resistance of each component is equal to the sum of the resistances of all the others.

This means that the capacitor will have a 1:1 resistance to any current flowing through it. In this case, the current will flow in one direction only, which is in the opposite direction from the direction in which it was originally connected.

Table of Contents

Is GMAW the same as MIG?

MIG/MAG welding is also known as gas-shielded metal arc welding (GMAW) and is one of the welding processes that uses a protective gas shield. The gas is then injected into the molten metal, causing it to expand and solidify as it cools.

As the gas expands, it creates a magnetic field that pulls the material away from the shield, creating an arc that can be seen from a distance of several hundred feet. In some cases, the arc may be visible to the naked eye, while in other cases it may take a few seconds to appear.

Because of this, this process is sometimes referred to as a “magnetic welding” process.

What is the difference between GMAW and SMAW?

SMAW, welders must periodically stop to change out for a fresh electrode. In GMAW, by contrast, the wire electrode feeds automatically into the spool gun. In addition to reducing the number of welds per hour, GSMW also reduces the amount of time it takes to complete a weld, which can be a significant time-saver in some applications.

What is the difference between GTAW and GMAW welding?

When gas metal arcs are used, the electrode is a type of consumables that melt down due to the heating of the metal. The electrode is not melted down under the intense heat of the GTAW process. In both cases, the electrodes are heated to a high temperature and then deposited on the weld braid.

First, while in the case of gas welding, heat is used to melt down the metal electrode and deposit the molten metal onto the welding bead, for the gas process it is the other way around. In this case, hot gas is injected into the arc furnace and the heat from the furnace is transferred to the hot electrode.

As a result of this transfer of heat, gas electrode becomes hot enough to be melted. The molten electrode then cools down and solidifies into a solid. This process is known as solidification. Second difference is that in both gas and gmaW processes, welds are welded in a continuous fashion. For this reason, both processes are used for high-temperature applications such as automotive, aerospace and medical applications.

What gas is used for GMAW?

The main gases used in GMAW process are inert gases (argon and helium) and small quantities of oxygen or carbon dioxide. It is most effective in shielding the arcs and blanketing them with a thin layer of gas when it is heavier than air. In the process, the gas is heated to a temperature of about 1,000 degrees Celsius (2,500 degrees Fahrenheit) in a vacuum chamber.

The gas then passes through a series of filters to remove impurities, such as carbon monoxide and hydrogen cyanide, before it is injected into the reactor core. This process is known as ionization, and is the same process that is used to purify drinking water in the United States. It is also a common method used by nuclear power plants around the world to reduce the amount of radioactive waste that must be disposed of in landfills.

Is GMAW manual or semi automatic?

Gmaw can be implemented as a manual, semi-automatic, or automatic process, and the flexibility offered by the process allows it to be used in a wide range of applications. The process consists of the following steps: (1) heating the wire, (2) forming the arc and (3) welding.

The wire is then heated to the desired arc temperature, which is determined by a number of factors, including the type of wire used, the material used to make the electrode (e.g., stainless steel, aluminum, copper, etc.), the length of time required to form an arc, as well as other factors such as the size, shape, thickness, density, temperature and other parameters.

Once the heat is applied, a small amount of molten metal is injected into the weld zone, causing the metal to solidify. This solidification process is referred to as “bonding” and is a critical step in the welding process.

Why is GMAW popular?

The gmaw process has an advantage over manual metal arc and gas tungsten arc because it has a high deposition rate. It is brought about by the high ratio of current to wire diameter and the removal of the need to change the wire size during the welding process.

The process also has the advantage that it does not require the use of high-temperature arc welding equipment, such as the High Pressure Arc Welding (HPAW) system, which is used in the manual metal arc and gas-to-metal (G2M) arc systems. The process can also be used to fabricate a wide variety of metal parts.

For example, it is well suited for the fabrication of stainless steel, aluminum, brass, copper, nickel, titanium and other metals, as well as plastics and ceramics. In addition, the process provides a high degree of control over the size and shape of welds, making it suitable for large-scale production.

Which metal transfer occurs in GMAW process?

The transfer modes in gmaw are short-circuiting, spray and globular. Modifications of the first two transfer modes are a recognized variation of these three modes.

G-MOSFETs are designed to operate in a wide range of temperature ranges, from -40°C to +250° C. They are also capable of operating at temperatures as high as +500° F. In addition, they can operate at extremely high voltages, up to 100,000 volts.

These characteristics make them ideal for use in high-voltage applications such as supercapacitors, superconductors, lasers, etc.

Is GMAW the same as TIG?

TIG welding uses a tank and inert gas to shield the weld. The electrode becomes part of the weld when it is consumed by heat in both GMAW and SMAW. TIG is the only one that carries the arcs, but is not consumed. The heat of a welding torch can be mitigated by the use of germanium.