The average wage for new welders is $20 per hour. If you are just beginning and need experience, lower pricing is great. You can begin charging between $20 and $30 per hour once you have a few years of experience. The hourly rate will go up as you get more experience.

Table of Contents

How much does it cost to preheat aluminum for welding?

T6 properties will be destroyed if you preheat the aluminum in the range of 300 to 600 degrees F. In general, preheat is never required to weld aluminum alloys. The temperature should be limited to 200 degrees or less if you want to preheat. The hot area will be hotter than the cold area, and vice versa.

For example, if you are welding a piece of aluminum that is about 1/4 inch thick and has a thickness of about 3/8 inch, then you will need to heat it to at least 400 degrees Fahrenheit before welding it. This is because the metal will have a higher melting point at this temperature than it does at room temperature.

You can do this by using a heat gun, but you must be careful not to burn yourself or your hands while doing so.

How many inches can a welder weld in an hour?

The average welder is able to complete about 140 inches of work per hour. The diameter of the pipe does not affect the number of welds per hour. Depending on the size and complexity of your project, you can get an hourly rate of welders in the range of $20 to $30 an hour.

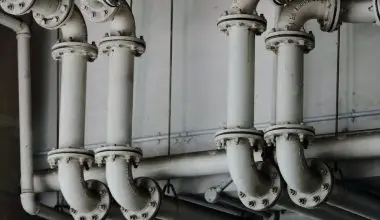

Pipeline welding can be done in a variety of ways, but the most common method is to use a hand-held welding torch. A torch is a type of welding tool that is used to heat metal to a high enough temperature to melt the metal and create a weld.

This process is called a “hot-air” welding process, and it is very similar to welding with a torch, except that the heat is applied directly to the weld, rather than being spread over the entire surface of a piece of metal.

Hot air welding is also referred to as “air welding” because it uses air as a heat source instead of fuel, which is typically used in conventional welding.

How much does it cost to MIG weld?

The cost for the mesh wire. The carbon steel e70s6 mig wire costs $1 per pound. The hourly cost of the MIG wire is $3/hour. Weld wire cost is 12.5 cents. The weight of the weapon is determined by the number of parts.

How much does it cost to start welding?

How much do you want to spend? $200 to $400 for a quality welding machine is what you’ll spend to get started. Most home centers only carry one or two models, so check online to see the range of what’s available. If you want to use a 120-volt welder to cut metal, it’s not a good idea to use it powered by a conventional outlet.

Why do welders drink milk?

A condition known as Metal Fume Fever can be caused by the fumes released when welding, cutting, or brazing galvanized steel. Milk is thought to help rid the body of toxins that come from welding galvanized steel. Milk is a good source of calcium, magnesium, potassium, and other minerals. Milk also contains calcium carbonate, which is used as a binder in the manufacture of plastics and ceramics.

How much a welder can weld in one day?

Depending on setup time, prep time, the type of job you are welding, machine maintenance, cool downtime, and any rework that needs to be done, this all depends on you. If you want to get the most out of your welders, you need to make sure that they have the right tools and equipment to do the job.

How many amps do I need to weld aluminum?

When other variables are constant, you should use 1 amp for every 1 inch of metal. When other factors are the same, you will need around 125 Amps if you want to make a piece of aluminum. For example, let’s you weld a piece of 1-1/2 inch aluminum.

If you were to use 125 watts, that means you would need to heat up the entire piece to 1,000 degrees Fahrenheit. This is a lot of heat, and it would take a long time to cool the piece down to room temperature. You would also have to be careful not to overheat the metal, as this could cause the weld to fail.

Why do aluminum welds crack?

Hot cracking, or solidification cracking, occurs in aluminum welds when high levels of thermal stress and solidification shrinkage are present while the welds are undergoing various stages of heat treatment. Solidification cracks occur when the temperature of the molten metal exceeds the melting point of aluminum. This occurs because the aluminum melts at a lower temperature than the metal that is being welded to it.

When this occurs, the melted aluminum solidifies into a hard, brittle, and brittle metal. Solidification is the most common type of cracking that occurs during the welding process, but it is not the only type. These types are known as non-thermal cracking and are more common than thermal cracking. They are also more difficult to detect because they do not occur in the same areas as thermal cracks.

How many feet per hour can you weld?

A conservative number for shop welding is 10 feet an hour. Easy and difficult work are averaged out. At the job site I am visiting, the welders don’t get any more than 3 feet an hour and it takes a welder and I about 10 minutes to get a job done.

If you are going to be working in the shop for a long period of time, you will need to learn how to work in a shop. You will also need a good set of tools to do the work. If you have never welded before, it can be a little intimidating at first, but once you get the hang of it you’ll be amazed at how easy it really is.