Canadian welding inspectors are eligible for the certified welding inspector or certified associate of applied science designation under the reciprocity program. CWB program is administered by the National Institute for Occupational Safety and Health (NIOSH) in collaboration with the U.S. Department of Labor (DOL) and the Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF).

Table of Contents

What is the difference between a qualified Welder and a certified Welder?

Society certification is only awarded through a specific process. Most of the time, qualification is done by companies and contractors who want their employed welders to perform specific welding on specific types of materials. The most common is the National Institute for Occupational Safety and Health (NIOSH) certification, which is awarded by the U.S. Department of Health and Human Services (HHS).

NIOSH is a federal agency that certifies occupational safety and health (OSHA) standards. It is not a state or local government agency, but rather an independent, non-profit organization that works to protect the health and safety of workers in the United States and around the world.

These include the Federal Energy Regulatory Commission (FERC), the Bureau of Land Management (BLM), and the Environmental Protection Agency (EPA). These agencies are all part of the federal government and are responsible for regulating the production, use, and disposal of hazardous materials on federal lands and in federal waters.

Who can claim CWB?

If you earn working income, you can be eligible for the canada workers benefit. If you are not a Canadian citizen or permanent resident, you may be eligible to apply for CWB if: you have been employed for at least one year in a job that requires you to be physically or mentally able to perform the duties of the job, and you meet the other eligibility requirements.

You must have worked in the same job for a minimum of 12 months before you apply. If you do not meet these requirements, your application will not be considered. For more information, go to the Employment Insurance (EI) website at www.eic.gc.ca or call Employment and Social Development Canada at 1-. For more information, go to the Employment Insurance (EI) website at www.eic.gc.ca or call Employment and Social Development Canada at 1-.

You can apply online, by mail or in person at a Service Canada office.

What is a Level 2 welder?

Welder ii joins, fabricates, and repairs metal and other weldable material by applying appropriate welding techniques. Analyzing blueprints, specifications, diagrams or schematics to determine the proper welding process. II inspects completed welds to determine their structural integrity. II are responsible for the safety of all welded materials.

They must be able to perform all welding operations safely and with minimal risk to themselves or others. I must have the ability to supervise welders III, IV and V, as well as other members of the Welding Team, to ensure safety and quality of work.

What is a Class 1 welder?

A structural weld requires the most stringent level of inspection. The determination of a Class 1 weld is the responsibility of the designer and should be noted in the design specifications. (b) A Class 2 or Class 3 weld shall not be welded unless it meets the requirements of paragraph (b)(1) of this section and is identified by the manufacturer as being a Type 1 or Type 2 weld.

The manufacturer shall identify the type of weld that is to be used in a particular application. For example, if a steel plate is used to support a structure, the plate may be identified as Type I, II, III, IV, V, or VI. III weld may also be referred to as an “intermediate” or “low” grade weld, depending on the grade of steel being used.

What is the easiest welding position?

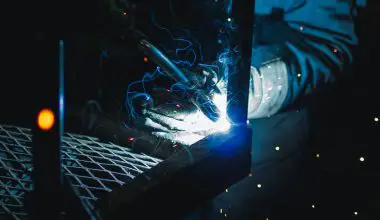

The flat position weld is often the first weld that new students learn, and is also referred to as a “downhand” position. The metals to be joined are placed flat, and the welder passes the electric arcs over them, moving across the workpiece in the direction of the arcs.

The arc is then passed over the metal again, this time to the other side. This is repeated until all the metals have been welded. If the welds are not perfect, they can be re-welded until they are.

It is important to remember that the welding process is a series of steps, each of which must be completed before the next step can begin.

For example, if a weld has been made on one side of a piece of metal, but not on the opposite side, it will not be complete until it is completed on both sides at the same time.