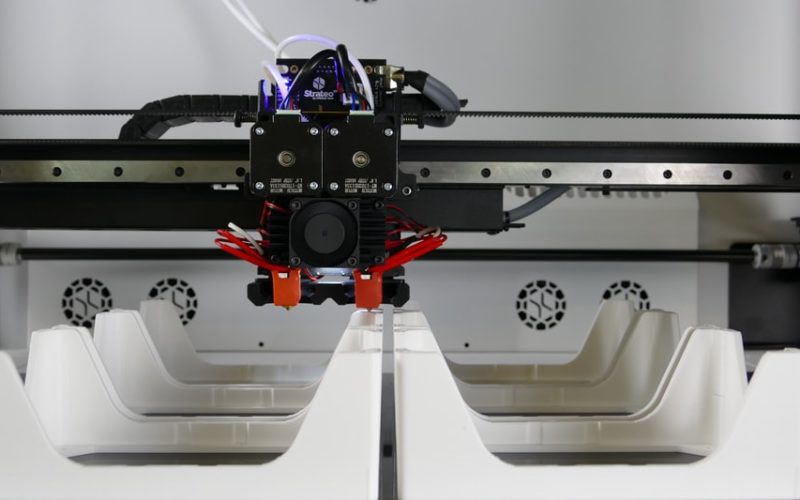

Adding material refers to the creation of objects byitive manufacturing. Additive manufacturing is a form of 3D printing. Additive objects are created by adding material, as opposed to removing material. 3D printers use a variety of materials to create objects, including plastics, metals, ceramics, composites, and other materials.

In addition to these materials, the printer can also be equipped with other components, such as electronics, sensors, actuators, motors, etc. The printer is capable of creating objects of various shapes and sizes, which can be used for a wide range of applications, ranging from prototyping to production.

For example, in the case of a 3-D printer, a user can create a model of the object that can then be printed out, or the user may be able to modify the model and print out a different version of it.

This allows users to experiment with different materials and designs, as well as to customize their objects to their own needs and preferences.

Table of Contents

Is 3D printing the same as additive manufacturing?

Additive manufacturing and 3D printing are the same process. The process of building parts by joining material layer by layer from one material to another is referred to in both terms.

How is 3D printing an example of additive manufacturing?

3D printing process called Additive Manufacturing. This process builds parts layer by layer by depositing material according to digital 3D design data. Additive manufacturing is a synonym for 3D printing. In this article, we will discuss the advantages and disadvantages of this process, as well as how it differs from traditional manufacturing methods.

Why use the term additive manufacturing?

The process of creating an object by building it one layer at a time is referred to as additive manufacturing. It is the opposite of subtractive manufacturing, in which an object is created by cutting away at a solid block of material until the final shape is achieved. In the case of a 3D printer, additive manufacturing takes place in the form of layers.

Each layer is made from a different material, such as plastic, metal, or wood. The material used to build each layer determines the shape of the object. For example, if you want to make a cube, you would start with a piece of wood, then add a layer of plastic to it, and so on, until you have a finished cube.

How 3D printing is changing manufacturing?

As technology in 3d printing has improved, the ability to make larger items as well as more detailed objects has become commonplace. Some manufacturers are using 3D printing technology to make lighter airplane parts, as well as small-scale models used to prototype and test new products. 3D printers are also being used in the manufacturing of medical devices.

For example, a team of researchers at the University of California, San Francisco (UCSF) has been working on a new type of implant that can be printed in a matter of hours. The device, which is designed to help people with spinal cord injuries, is made up of a series of layers that are printed on top of each other to form a three-dimensional structure.

Once the device is printed, it can then be attached to the patient’s body, allowing them to move their limbs without the need for a prosthesis.

Are 3D printed goods as good as those manufactured traditionally?

“What are the advantages & disadvantages of 3D Printing & Traditional Manufacturing?” 3D printed parts are typically 1/3 weaker than traditonally manufactured parts, however 3D printing can make parts which are 3/4 stronger than traditional manufacturing methods. 3D printers can also be used to create parts that are stronger, lighter, and more durable than those made with traditional methods of manufacturing.

For example, if you want to make a part that is stronger and lighter than a traditional part, you can use a 3d printer to print the part and then use the traditional method of machining and welding to assemble it. However, this is not always the case.

If you are looking for a lighter and stronger part to use in your next project, then you may be better off using a conventional manufacturing method such as a lathe, milling machine, or CNC machine.

What is additive manufacturing quizlet?

Manufacturing refers to a process by which digital 3D design data is used to build up a component by depositing material layer by layer. 3D printing” is a synonym for “additive manufacturing” Additive manufacturing has been around for a long time, but it is only recently that it has become a viable option for large-scale manufacturing of complex parts.

In the past, it was only possible to print a single part at a time. However, with the advent of the additive process, you can now print multiple parts at the same time using a variety of materials, such as plastics, metals, ceramics, and polymers. This allows you to create parts that are more complex than ever before.

For example, if you want to make a part that can be printed in multiple colors, then you will need to use multiple layers of different materials to achieve the desired effect. You can also print parts with different shapes and sizes, which is a great way to add a lot of variety to your designs.

What is an advantage of additive manufacturing additive manufacturing?

More manufacturing steps, material and labor costs are required for traditional, complex parts. It increases inventory because the time to create and assemble them is longer. You can save money and time by printing the assembly as a single piece with Additive Manufacturing. In this case, the layer is plastic, but you could use a variety of other materials, such as metal, glass, ceramic, or even paper. Once the layers are printed, they can be glued together to form the final part.

They’re also used to make parts for cars and airplanes, as well as for the construction of homes and other structures. But the technology is still in its infancy, with only a handful of companies in the U.S. and around the world currently using it for manufacturing.

What means 3D printing?

computer. 3D printing uses layers of material to create a solid object. In the case of the 3-D printer, the object is created by depositing a layer of a material, such as plastic or metal, onto a heated bed.

The material is heated to a temperature that allows the material to melt and solidify. Once the melted material has solidified, it is removed from the bed and a new layer is added. This process is repeated until the desired object has been created.